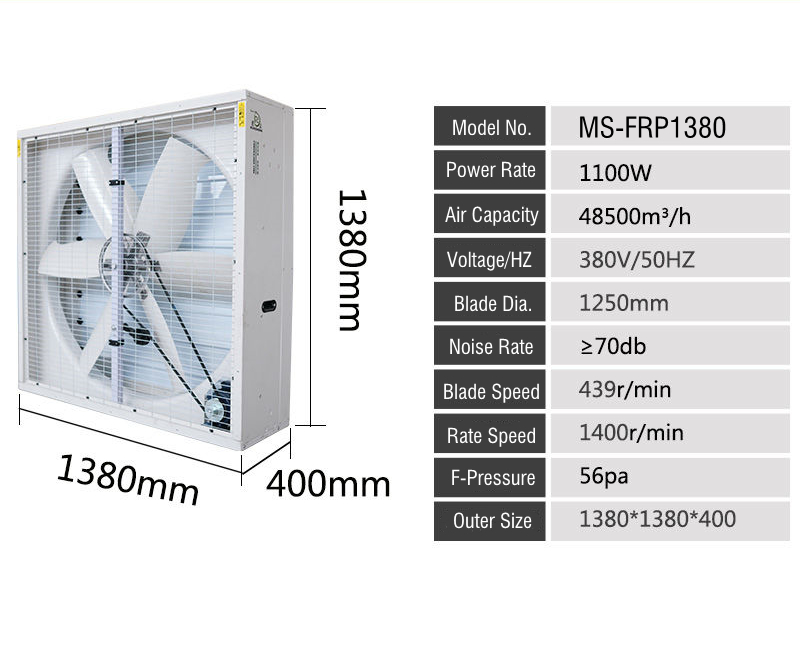

Drop Hammer Ventilation Fiberglass Fan Industrial Wall Mount FRP Exhaust Fans With Shutter

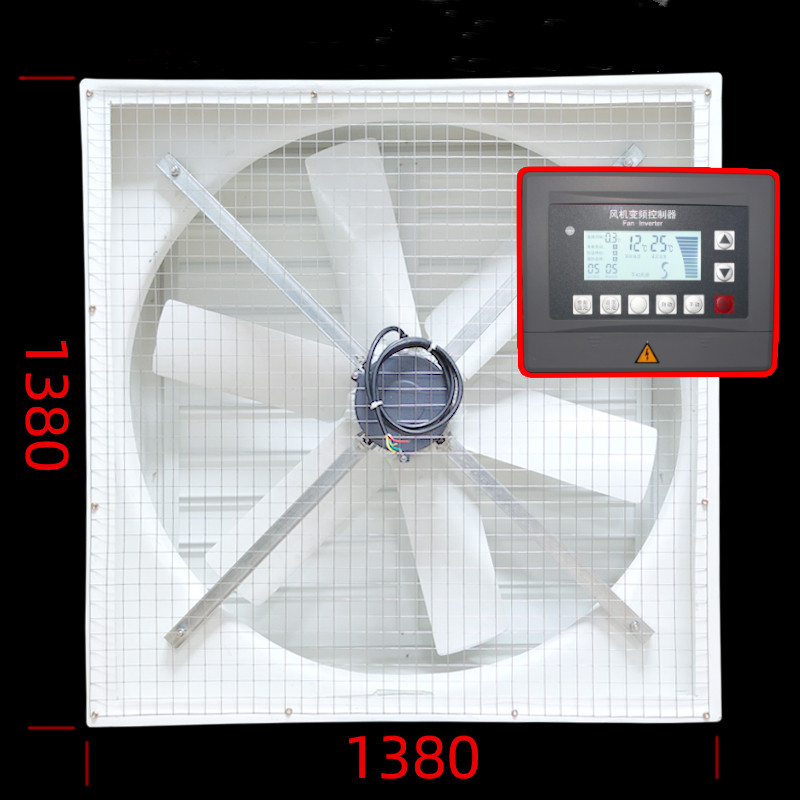

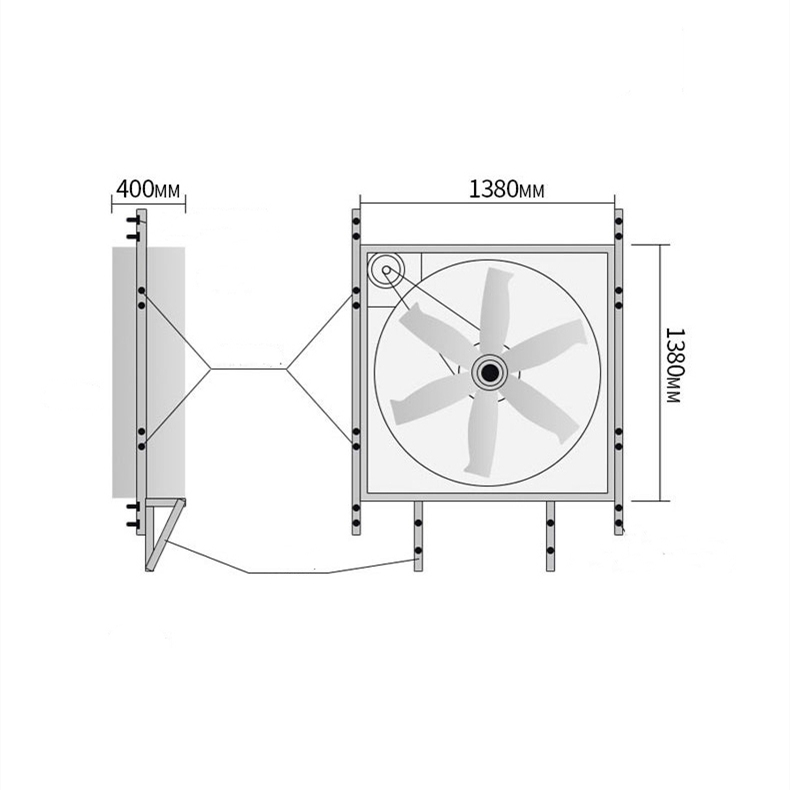

1380-Model 54”(inch) Heavy duty wall mount fiberglass exhaust fans

Table of Content

1. What is wall mount fiberglass exhaust fans?

2. What are components of drop hammer wall exhaust ventilation fans?

3. What is the difference between drop hammer exhaust fans and negative pressure fans?

4. What are the factors to consider when selecting an exhaust fan for wall mounting?

5. What is the advantage of wall mount drop hammer fiberglass exhaust fans?

1. What is wall mount fiberglass exhaust fans?

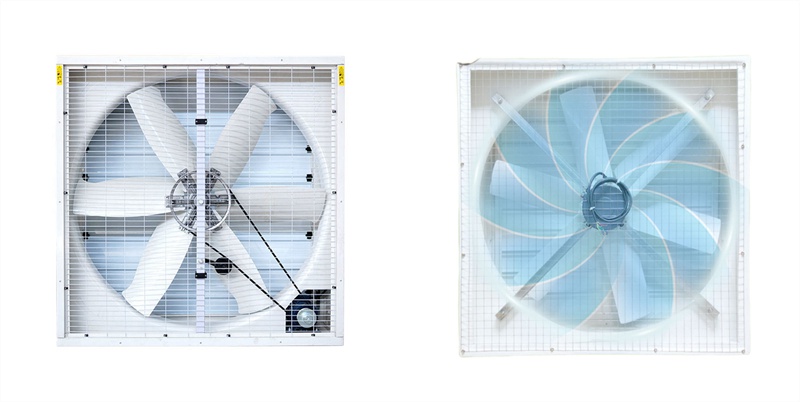

Wall mount fiberglass exhaust fans are exhaust fans that are mounted along interior or exterior walls near husbandry cage ,livestock crate or in areas that experience extreme levels of moisture and exhaust gasses. Marshine exhaust fans help cool equipment and prevent early corrosion and deterioration of metal surfaces. Applications like ventilation in poultry farm, greenhouse, livestock farm, factory and warehouse.

However, not only do Marshine wall mount fiberglass exhaust fans protect your equipment, they also provide a healthy, safe, and more productive work environment for employees.

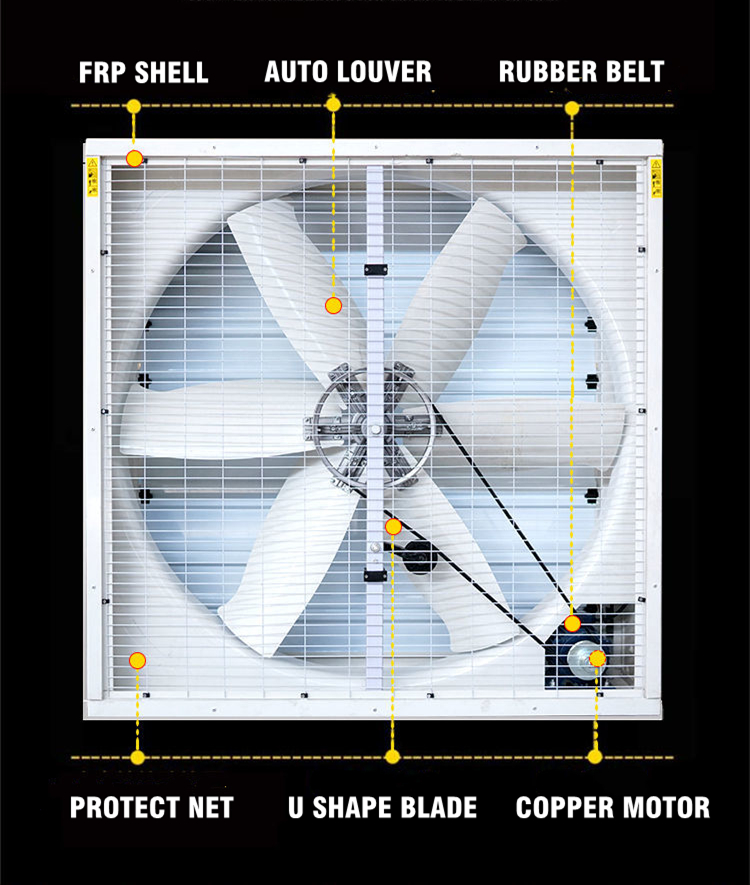

2. What are components of drop hammer wall exhaust ventilation fans?

Fan Shell Body:

For 54 inch wall mount fiberglass exhaust fans which is most often used in the greenhouse and poultry farm. It made of FRP, which has the characteristics of stability, durability and high corrosion-resistance and rust-resistance. Marshine Fan impeller adopts sheet molded casted fiberglass impeller, bending strength is not less than 196 mpa, each part adopts smooth excessive, smooth appearance, no cracks, gaps, burrs and other defects, the overall effect is good.

Motor:

All motors produced by Marshine Industry which are copper motors with simple structure, stable performance, lower price and convenient maintenance. The energy efficiency ratio of motor are up to the numbers of internal copper coils and steel sheet, Marshine motors use famous brand bearings, silicon steel sheet and enameled round copper wire with higher guaranteed performance.

Shutters:

like the fan frame, there are many material choices for the shutter material, hot galvanized sheet steel with zinc thickness of 275g/㎡ will be a better choice, with higher anti-corrosion performance, longer service life, no deformation, no rust and more reliable operation.

Belt Pulley:

There are materials of belt pulley in the market, which include stainless iron, plastic and Aluminum-magnesium alloy by die-casting. The stainless iron material is heavy, it will result in loud noise and low wind speed. The plastic pulley is of low durability, the belt pulley of Marshine is made of high strength aluminum-magnesium alloy by die-casting.

Fan Blade:

Blades are the top most factor which affects the ventilation capacity of an poultry or greenhouse exhaust fan, the blade ventilation performance is up to the design and size of the blade, however, the durability and corrosion-resistance of the fan blade is up to the material of the blade, blade materials are fiberglass the thickness are mostly 13mm or 18mm.

Drop Hammer:

High quality Nylon material control the shutter opened and closed automatically to achieve dustproof, waterproof and elegant appearance. It also can control the blown or extracted, which is the choice of cooling and ventilation in modern workshops.

Safety Net:

the safety net seems simple but it is very important, it is easy to have rust if the density of safety is not enough with high factor risk, the anti-rust doesn’t work out. You can choose hot-dip galvanized wire material, which has strong oxidation resistance, high welding density, small mesh, higher safety performance, and strong corrosion resistance.

3. What is the difference between drop hammer exhaust fans and negative pressure fans?

|

Item No. |

Dimensions(mm) |

Power(W) |

Air Flow |

Voltage/Frequency |

Noise |

Rotation Speed |

Net Weight |

|

560# |

560x560x440mm(22”x22”x17”) |

250W (3p) |

10000 m³/h 5900CFM |

380V/50Hz (customizable) |

≤45db |

950rpm |

35kg |

|

680# |

680x680x450mm(26"x26"x18”) |

250W (5p) |

12000 m³/h 7200CFM |

380V/50Hz (customizable) |

≤45db |

820rpm |

40kg |

|

850# |

850x850x480mm(33"x33"x19”) |

370W (8P) |

17000m³/h 10000CFM |

380V/50Hz (customizable) |

≤53db |

620rpm |

45kg |

|

1060# |

1060x1060x550mm(42"x42"x22”) |

550W (10P) |

28000m³/h 16600CFM |

380V/50Hz (customizable) |

≤55db |

560rpm |

50kg |

|

1260# |

1260x1260x560mm(50"x50"x22”) |

750W (10P) |

37000m³/h 22000CFM |

380V/50Hz (customizable) |

≤65db |

520rpm |

65kg |

|

1460# |

1460x1460x580mm(57"x57"x23”) |

1.1KW(10P) |

45000m³/h 26500CFM |

380V/50Hz (customizable) |

≤65db |

450rpm |

75kg |

4. What are the factors to consider when selecting an exhaust fan for wall mounting?

Some factors to consider when selecting Marshine exhaust fan for wall mounting are power sources (single phase or three phase power) air stream cleanliness, whether gravity or actuator shutters are necessary, level of sound sensitivity, and whether or not a belt driven or direct driven exhaust fan is preferred.

1. Height of orifice, angle and size of fan blade, and power of motor can directly affect the air volume of exhaust fan.

2. The one piece automotive bearing can reduce the noise of exhaust fan in operation, fully open-close design of shutter can prevent exhaust fan from rusting, and it also extend the service life of exhaust fan.

3, The belt pulley uses blast-sanding treatment, eliminate internal stress to further improve its own rigidity and stability, the shutter can be fully open to 90 degree with the use of heavy hammer that ensure to reach lowest air resistance and maximum air volume of the fan.

4. Belt-driven wall mount exhaust fans are able to handle large volumes of air at low static pressures. This type of exhaust fan runs more quietly and allow greater control over fans speeds than direct-drive exhaust fans.

5. Direct-drive exhaust fans have their motor mounted on the fan shaft, are more compact, and have fewer moving parts than belt-driven fans.

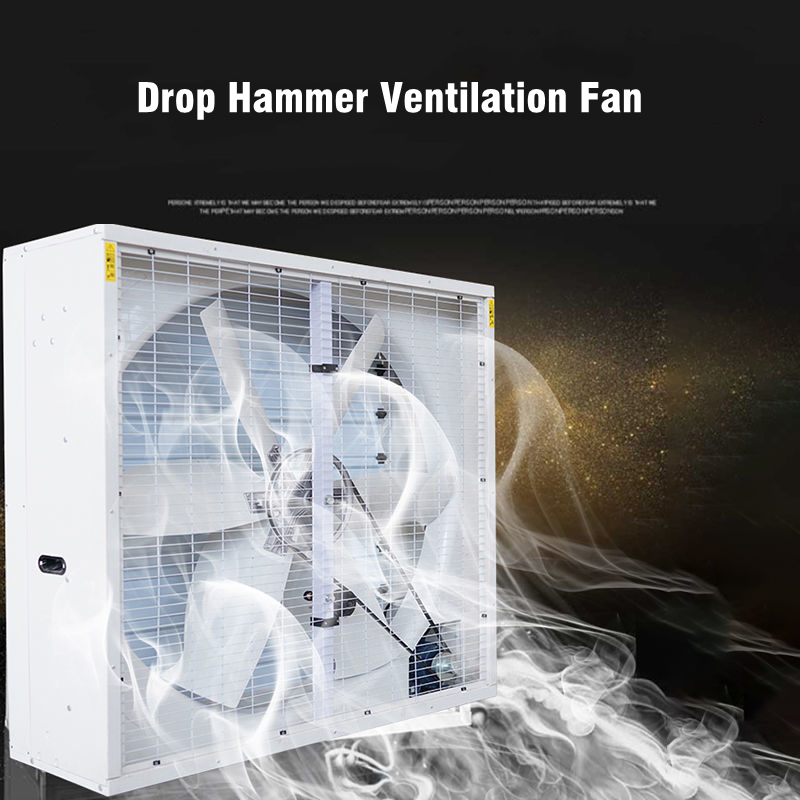

5. What is the advantage of wall mount drop hammer fiberglass exhaust fans?

1. Wall mounting exhaust fan design with fiberglass shutters and frames with good corrosion resistance, light weight, high strength, convenient transportation and easy installation.

2. Through-wall mount type, clean and tidy small wind resistance, good transport capacity. The blades are enclosed with wire guards, can be customized to be OSHA compliant.

3. Capable of venting reactive, non-explosive fumes. anti-fouling and anti-moth.

This special medium is free from contamination by bacteria and other organisms.

4.The Marshine drop hammer fiberglass exhaust fans removes excess heat, moisture, dust and odours in farms make environment good heat and cold resistance and the fresh air naturally flows into the room for ventilation.

5. With automated shutters to keep out the rain, bugs and dust open easily with minimal airflow resistance and beautiful appearance, compact structure, anti-aging, low power consumption, low noise, reliable operation, convenient installation and maintenance.