Cabinet Box Fiberglass Livestock Farm Ventilation Shutter Mounted Window Exhaust Fan With Louvers

850-Model 33” (inch) Ventilation Window Exhaust Fan

Table of Content

1. What is a FRP Ventilation Window Exhaust Fan?

2. What are the components for ventilation window exhaust fan?

3. What is the measure size of Ventilation Window Exhaust Fan:

Model MS-680, MS-850, MS-1060, MS-1260,MS-1460

4. What is the scope application of ventilation window exhaust fan?

5. How does the poultry ventilation window exhaust fan working?

1. What is a FRP Ventilation Window Exhaust Fan?

FRP industrial ventilation window exhaust fan is the use of air convection, the cooling principle of Marshine negative pressure ventilation, by the installation location to the door or window natural breathing in the fresh air, indoor hot gas rapidly compulsory reduction outdoor, any problem of poor ventilation can improve the mechanical, reasonable decorate cooling ventilation effect can reach more than 90%, after the use of industrial ventilation fan, can let air movement, air changes per hour can reach 60 ~ 120 times, It can give you create a smooth, fresh air, good ventilation and comfortable working environment, improve indoor hot, bad breath, lampblack, noxious gas, and other issues.

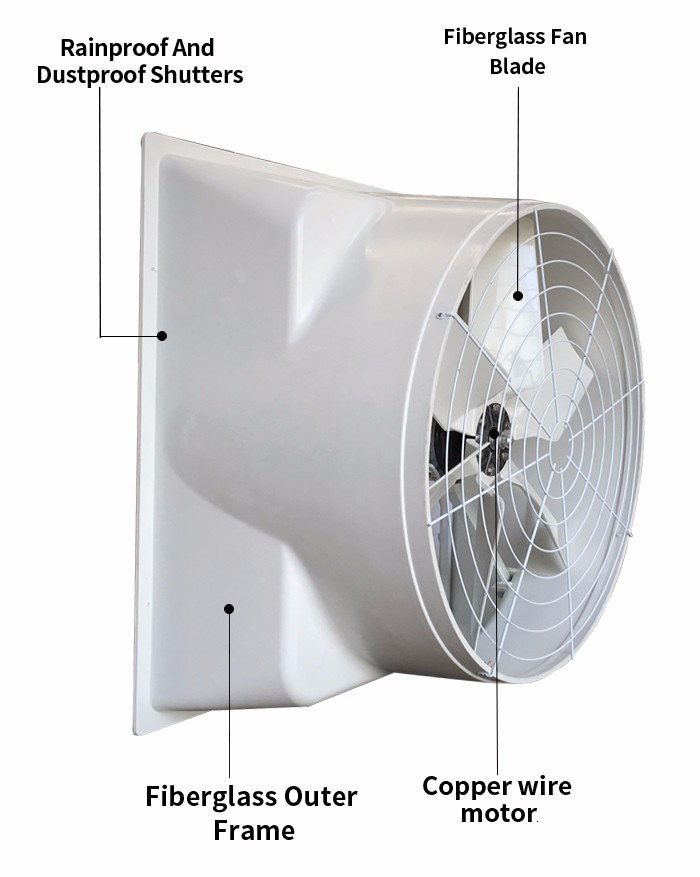

2. What are the components for ventilation window exhaust fan?

For the material of ventilation window exhaust fan, fiberglass among which the 304 stainless steel is the most durable material to choose, and it comes with high corrosion-resistance and rust-resistance. However, the cost of 304 stainless steel is too highest. That’s why fiberglass FRP SMC fan frame are used in most cases.

Fan Frame Thickness:

For 26 inch Marshine ventilation exhaust fan which is most often used in the greenhouse and poultry farm, 10mm thickness of the main fiberglass ventilation exhaust fan body will be very stability and durability. And Marshine exhaust fan border thickness 18mm for comparably higher durability and strength installation. There are also manufacturers in the market who make the exhaust fans with 8mm thickness to meet the customers’ incredibly low budget for their projects, however, we don’t produce nor recommend this thickness to our customer for any kind of projects.

Shutters: As the fan frame, there are many material choices for the shutter material, fiberglass or PVC material will be a better choice, with higher anti-corrosion performance, longer service life, no deformation, no rust and more reliable operation..

Fan Blade: blades are the top most factor which affects the ventilation capacity of an poultry or greenhouse exhaust fan, the blade ventilation performance is up to the design and size of the blade, however, the durability and corrosion-resistance of the fan blade is up to the material of the blade, blade materials are fiberglass.

Belt: There are two types of belt you can select, but we will suggest you choose the B type belt because B type belt is 3 times longer service life than A type belt, and maintenance free.

Bearing: We recommend you use one piece deep groove automotive bearing, with special design of waterproof, high strength, lower noise, maintenance-free, and long service.

Motor: The fan motor’ rotor is made of metal strip with copper coil or aluminum coils, the price of aluminum coil is much lower than copper coil, but the mechanical properties and electrical conductivity of copper are better than aluminum.

Motor Stents: there are materials of motor stents in the market, which include stainless iron, plastic and Marshine FRP pultrusion profile. The stainless iron material is heavy, it will result in loud noise and low wind speed. The plastic pulley is of low durability, the motor stens of Marshine is made of high strength fiberglass pultrusion rectangle tubes.

3. What is the measure size of ventilation window exhaust fan:

|

Item No. |

Dimensions(mm) |

Power(W) |

Air Flow |

Voltage/Frequency |

Noise |

Rotation Speed |

Net Weight |

|

560# |

560x560x440mm(22”x22”x17”) |

250W (3p) |

10000 m³/h 5900CFM |

380V/50Hz (customizable) |

≤45db |

950rpm |

35kg |

|

680# |

680x680x450mm(26"x26"x18”) |

250W (5p) |

12000 m³/h 7200CFM |

380V/50Hz (customizable) |

≤45db |

820rpm |

40kg |

|

850# |

850x850x480mm(33"x33"x19”) |

370W (8P) |

17000m³/h 10000CFM |

380V/50Hz (customizable) |

≤53db |

620rpm |

45kg |

|

1060# |

1060x1060x550mm(42"x42"x22”) |

550W (10P) |

28000m³/h 16600CFM |

380V/50Hz (customizable) |

≤55db |

560rpm |

50kg |

|

1260# |

1260x1260x560mm(50"x50"x22”) |

750W (10P) |

37000m³/h 22000CFM |

380V/50Hz (customizable) |

≤65db |

520rpm |

65kg |

|

1460# |

1460x1460x580mm(57"x57"x23”) |

1.1KW(10P) |

45000m³/h 26500CFM |

380V/50Hz (customizable) |

≤65db |

450rpm |

75kg |

4. What is the scope application of ventilation window exhaust fan?

A. It is suitable for workshops with high temperature or peculiar smell, such as heat treatment plant, casting plant, plastic plant, aluminum profile plant, shoe factory, leather factory, electroplating plant, printing and dyeing plant and various chemical plants.

B. Suitable for labor-intensive enterprises: such as garment factory, all kinds of assembly workshop, Internet bar.

C. The greenhouse of horticulture is ventilated and the livestock farm is cooled.

D. It is especially suitable for places that need cooling and certain humidity. Such as cotton mill, wool mill, hemp mill, weaving mill, chemical fiber mill, warp knitting mill, texturing mill, knitting mill, silk mill, hosiery mill, etc.

E. It is suitable for warehousing and logistics in almost all places that need cooling, ventilation and ventilation, especially for industrial production workshops with high temperature or peculiar smell with good ventilation and cooling effect.

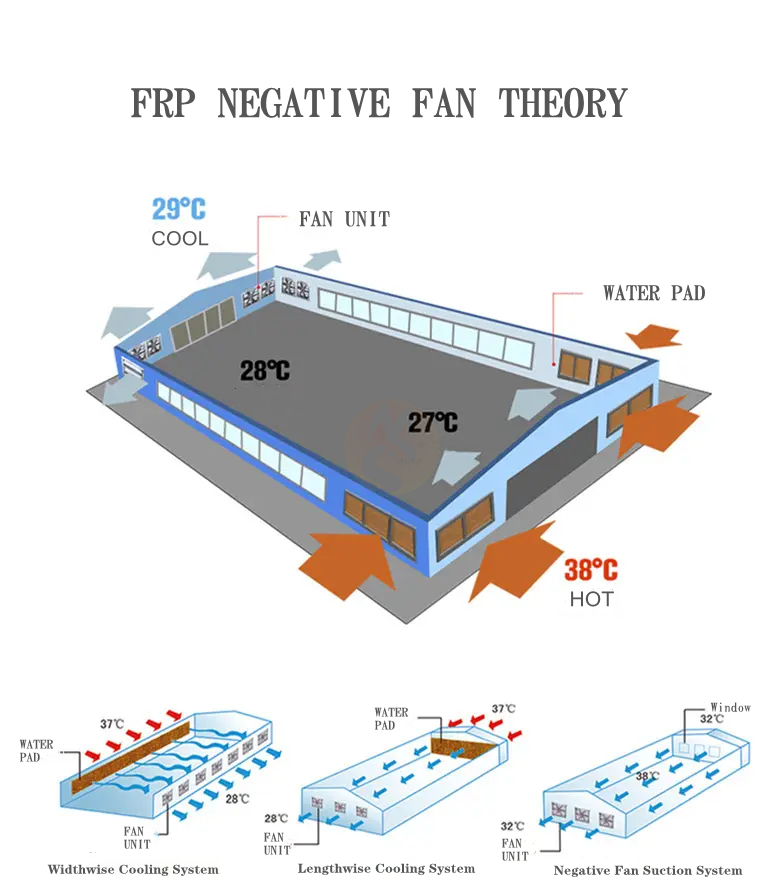

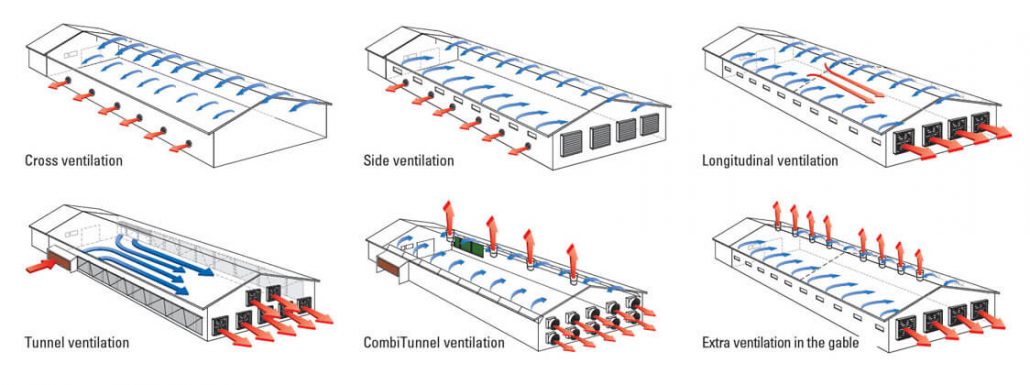

5. How does the poultry ventilation window exhaust fan working?

1. The poultry ventilation window exhaust fan exhausts the air to make the indoor pressure drop, and the indoor air becomes thinner, forming a negative pressure area, and the air flows into the room due to the pressure difference.

2. In the practical application of industrial plants, Marshine negative pressure ventilation fan is installed on one side of the plant, and the air inlet is on the other side of the plant.

3. The air from the air inlet to the ventilation fan forms convection blowing. In this process, the doors and windows near the Marshine industrial ventilation fan are kept closed, forcing air to flow into the workshop by one side of the door and window of the air inlet. The air is lined up and orderly from the air inlet into the workshop, flows through the workshop, and is discharged from the workshop by the industrial ventilation fans.

4. The ventilation rate can be as high as 99%. Through specific engineering design, according to the need to design ventilation speed and wind speed, high heat, harmful gases, dust and smoke can be discharged quickly from the workshop, poor ventilation problems can be solved once. Ventilation can be achieved within seconds of starting the fan.