Poultry Farm Chicken Broiler Fodder Feeding System for Chicken Poultry Feeding equipment

Poultry farm feeding system

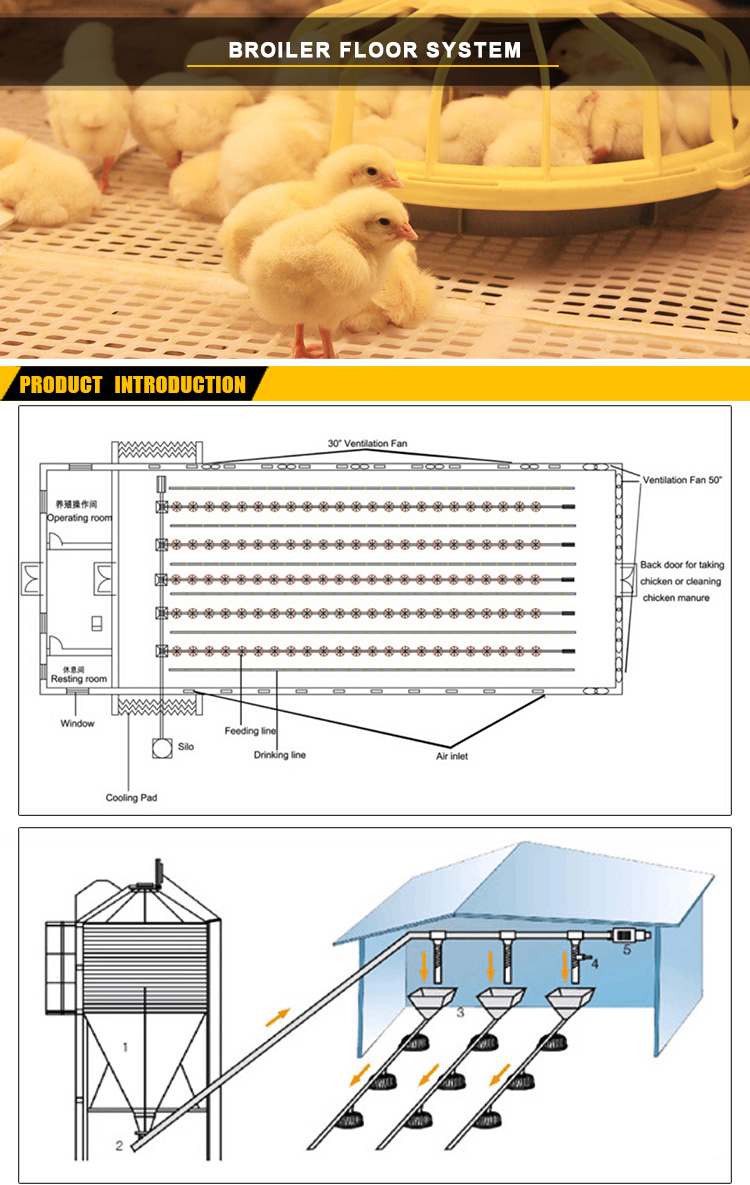

1. What is poultry farm feeding system and how does it work?

The poultry farm feeding system is composed of a hopper, a conveyor tube, an auger, several pan feeders, a suspension lifting device, a driving motor, and a feed sensor, etc. parts. The main function of the system is conveying the feed from the hopper to each pan feeder for chickens. The automatic operation of Marshine feeding system is realized by the feeding level sensor to control the work or stop of the motor.

The main function of Marshine feeding system is conveying the feed from the hopper to each pan feeder for chickens. The automatic operation of the system is realized by the feeding level sensor to control the work or stop of the motor.

2. What equipments include in complete set of poultry farm feeding system?

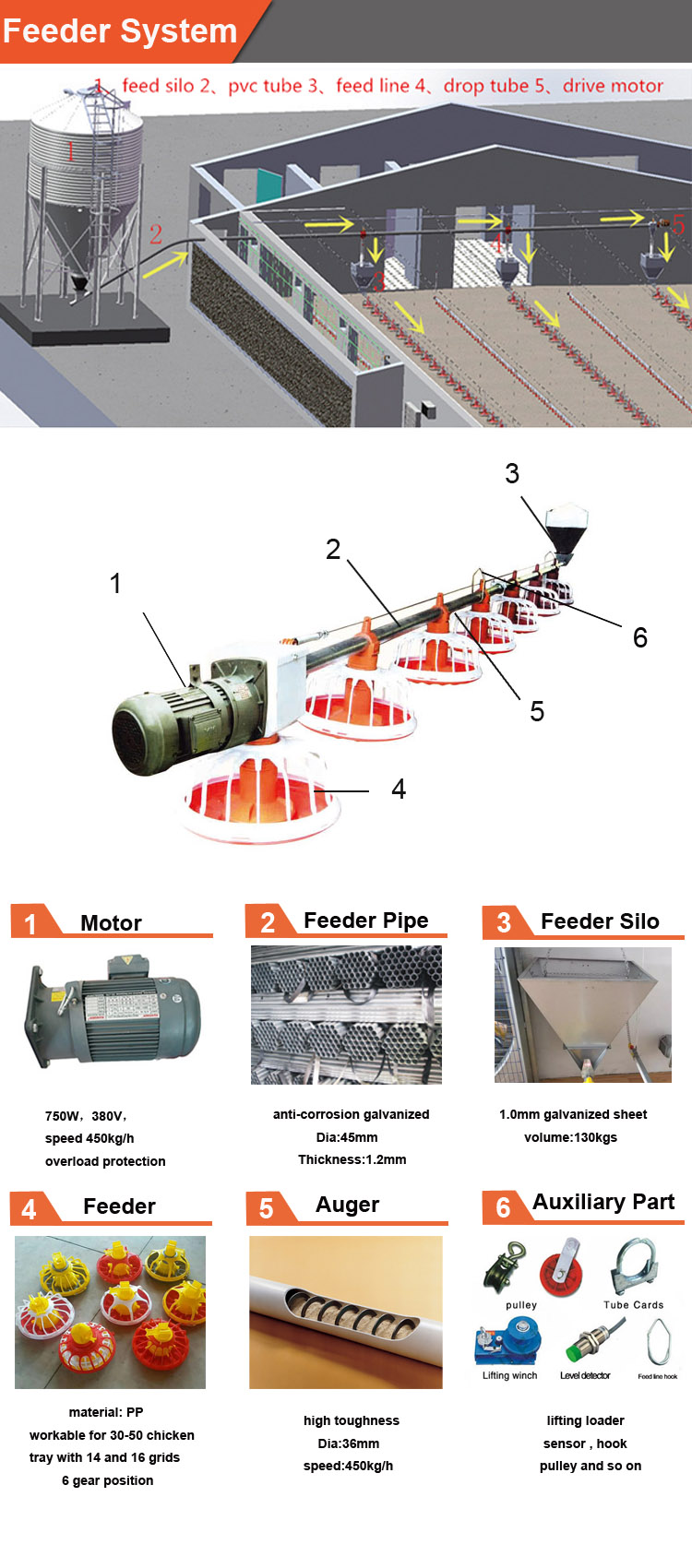

First. main fodder feeding system

The main feeding system composed of silo tower, transport pipe, auger, motor and feed level sensor. The function of Marshine feeding system is transport the fodder from main feed hopper into sub hopper and use feed level sensor automatic control the drive motor open or close the transportation to realize the fodder transport process.

Specification:

1. Main driving device:

Rate power: 0.75kW/1.1kW/1.5kW Voltage: 220V/380V Protection Grade IP55

Frequency rate: 50HZ

2. Feeding transportation system:

Feed pipe diameter: φ75mm* thickness 3.75mm Material: PVC

Auger: Spiral spring steel Plug plate: ABS plastic

Feeding capacity: 3000kg/h

Max transportation length: 120meter

3. Automatic high sensitive electric feed level sensor

Second. auxiliary fodder feeding system

The auxiliary feeding system composed of feed hopper, transportation pipe, steel auger, feed pan, handing rise and down device, electric motor and feed level sensor.

The function of Marshine auxiliary feeding system is transport fodder from hopper to every feed pan so that guarantee feeding the meat chicken.

It use the fodder level sensor automatic control the transportation motor open and close, so that reach the automatic food transportation solution.

The feed hopper volume 50kg/120kg, thickness 2.0mm HDG steel, V shape concentric hopper with 3500lbs feed pans.

Third, fodder transportation system

Fodder pipe: every 3 meter 3 holes or every 3 meter 4 holes

Diameter: φ45mm

Material: HDG steel pipe zinc contained: 275g/㎡

Thickness: 1.2mm

Spiral spring auger: import from South-Africa

Feeding Capacity: 450kg/hour

Fourth, Drive main motor

Motor rate power: 0.75kW/1.1kW/1.5kW

Voltage: 220V/380V three phase / single phase

Protection class: IP55 over load protective class F

Rate frequency: 50Hz/60Hz

3. What is the size and type of the automatic poultry farm feeding system?

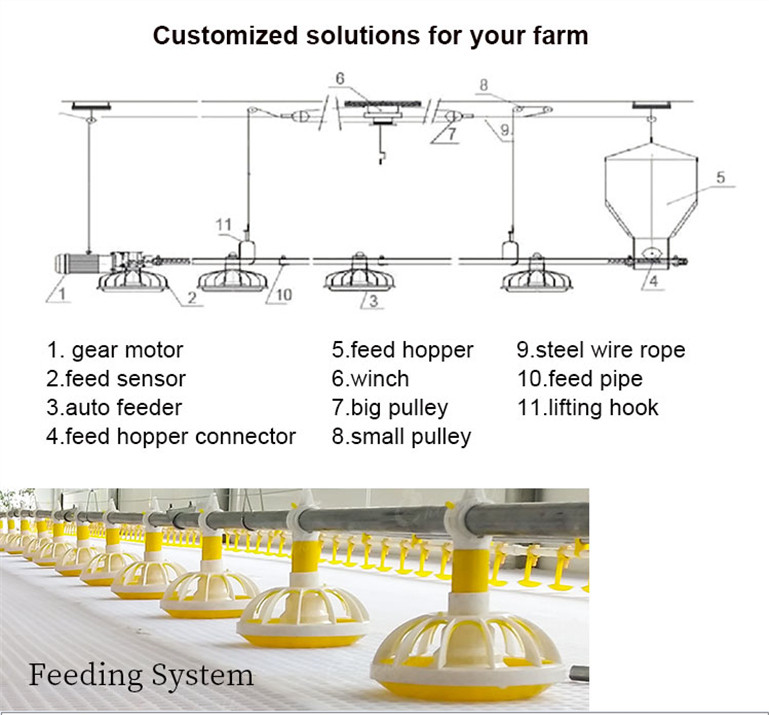

| 1. Feed Silo | 2mm thickness hot galvanized steel.

Size: diameter 2.65m, 6 legs, Actual capacity 90%. Feed density 0.65ton/m3. |

| 2.Vice Hopper

|

Size: 70Kg, 90Kg

Material: hot-dip galvanized sheet, thickness:1mm |

| 3.Feed Pipe

|

Feed pipe:

Diameter of feed pipe:Φ45mm Material: hot-dip galvanized sheet pipe with the zinc coating amount—more than 275m2. Helical spring auger: imported from South Africa, feeding ability:450Kg/h |

| 4.Feed Pan

|

4 feed pans/3m,

Feed pan capacity: 50-55 broilers/pan |

| 5.Control feed pan(with sensor)

|

imported from Germany

time delay range: 0-2hours The sensor is usually installed at the end of each Marshine feeding line which controls motor on and off to achieve feed delivery automatically. The motor will start working and convey feed when sensor doesn't touch feed, the motor will stop conveying feed when sensor touch feed. |

| 6.Driving motor

|

Taiwan brand

Power: 0.75Kw/1.1Kw/1.5Kw, Voltage:380V/220V/others, three-phase/single-phase Frequency:50Hz, AC current |

| 7.Connector box | Firm connection |

| 8.End tube | End tube position |

| 9.Anti-perching system | It prevents chickens from staying on the ground for too long. |

| 10.Lifting & Suspension | It's very convenient to adjust the feeding line height by winch. |

| 11.Hopper bin | Hopper bin position |

| 12.Cross beam | Cross beam position |

4. What are the advantages of automatic poultry farm feeding system?

1. Improve production efficiency, greatly increase production capacity, and have significant economic benefits

Te use of Marshine automatic feeding system to feed the chickens can ensure uniform feeding, so that the uniformity of chicken growth can be improved, and the laying hens can increase the egg production rate, prevents crop damage and provides comfort eating for chicken, efficiently to make sure the chicken gets food instantly.

2. Reduce manpower and greatly reduce production costs

The use of Marshine automated chicken raising equipment to raise chickens can automatically perform work instead of labor. This can save farmers the use of labor costs and reduce the cost of labor for farmers. The use of automated equipment is more convenient for mechanized operation, which can increase labor productivity to a large extent, that is, greatly reduce labor costs.

3. Easy to manage and reduce breeding risks

The use of Marshine automated equipment conducive to disease control and drug residue control, which creates conditions and lays the foundation for achieving the requirements of chicken hygiene and safety. The use of fully automatic poultry breeding equipment is the current direction to achieve intensive, standardized, efficient and high-quality breeding of layer and broiler chickens.