Corrosion Resistant FRP Cone Negative Pressure Ventilation Fan for Piggery Pig House

1060-Model 42” (inch) FRP Cone Negative Pressure Fan

Table of Content

1. What type of industrial fan is FRP cone negative pressure fan?

2. What are the components of FRP cone negative pressure fan?

Frame, Shell, Motor, Blade, Louver and Spare parts.

3. What is the detail specification of FRP negative pressure fan?

Model MS-680, MS-850, MS-1060, MS-1260,MS-1460

4. What is the advantages of FRP cone negative pressure fan?

5. Where is a negative pressure ventilation fans installed for commercial ventilation system?

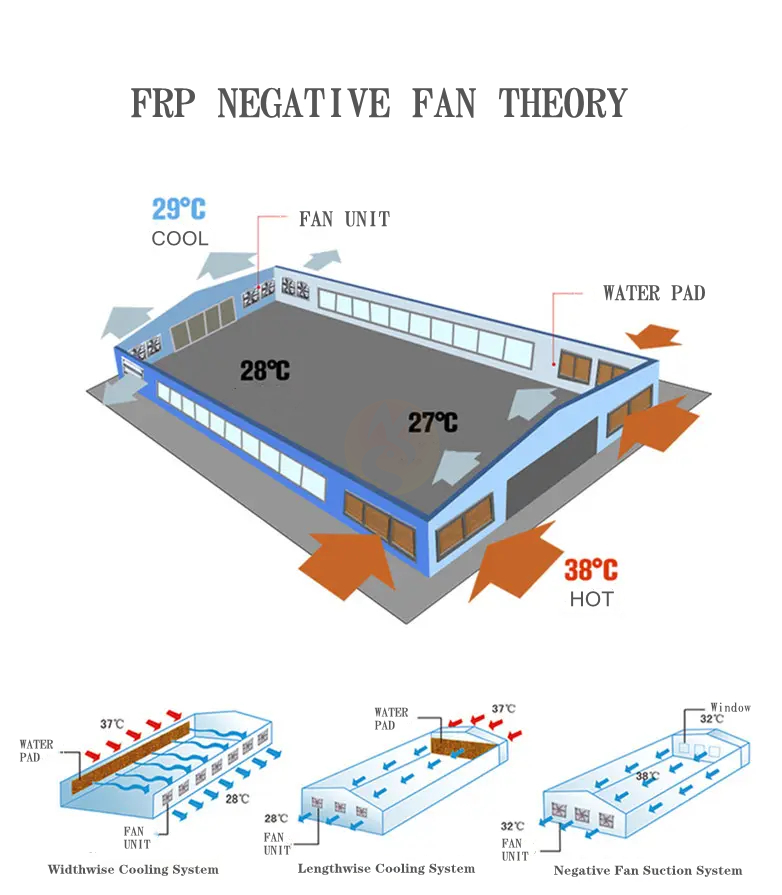

1. What type of industrial fan is FRP cone negative pressure fan?

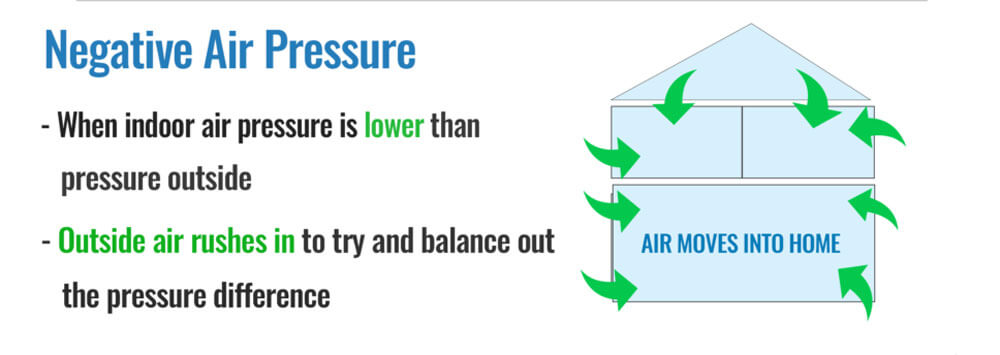

FRP cone negative pressure fan is a new design of livestock farming house ventilation equipments mainly used as trench fan and side fan solution. Marshine FRP negative pressure fan can exchange air through negative pressure, which can achieve the performance of air circulation, effectively remove the dirty gas such as NH3, H2S and humid air in the dung ditch and the breeding house, and eliminate the sultry heat, smoke, exhaust gas, dust, etc.

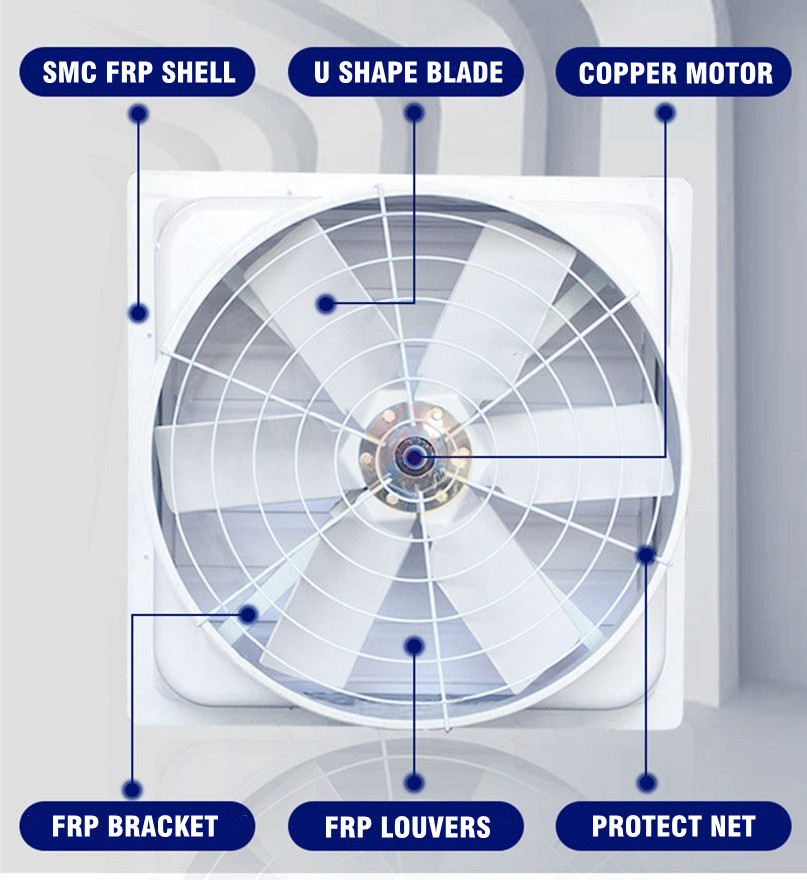

2. What are the components of FRP cone negative pressure fan?

Marshine negative pressure fan ventilator is composed of frame, support frame, motor, fan blade, air supply device, louver, protection net and other parts.

◆ The outer frame and wind blade are made of fiberglass mould, beautiful and durable;

◆ The fan is directly connected with the motor, simple and reliable, easy to maintain;

◆ The blades are calibrated by precise dynamic balance, operation is stable, with large air volume and low noise;

◆ The synthetic PVC louver with the principle of air forward flow is used to prevent flies and air backflow;

◆ The special high-performance low-speed powerful motor, reliable quality, long service life, better use effect.

3. What is the detail specification of FRP negative pressure fan?

|

Item No. |

Dimensions(mm) |

Power(W) |

Air Flow |

Voltage/Frequency |

Noise |

Rotation Speed |

Net Weight |

|

560# |

560x560x440mm(22”x22”x17”) |

250W (3p) |

10000 m³/h 5900CFM |

380V/50Hz (customizable) |

≤45db |

950rpm |

35kg |

|

680# |

680x680x450mm(26"x26"x18”) |

250W (5p) |

12000 m³/h 7200CFM |

380V/50Hz (customizable) |

≤45db |

820rpm |

40kg |

|

850# |

850x850x480mm(33"x33"x19”) |

370W (8P) |

17000m³/h 10000CFM |

380V/50Hz (customizable) |

≤53db |

620rpm |

45kg |

|

1060# |

1060x1060x550mm(42"x42"x22”) |

550W (10P) |

28000m³/h 16600CFM |

380V/50Hz (customizable) |

≤55db |

560rpm |

50kg |

|

1260# |

1260x1260x560mm(50"x50"x22”) |

750W (10P) |

37000m³/h 22000CFM |

380V/50Hz (customizable) |

≤65db |

520rpm |

65kg |

|

1460# |

1460x1460x580mm(57"x57"x23”) |

1.1KW(10P) |

45000m³/h 26500CFM |

380V/50Hz (customizable) |

≤65db |

450rpm |

75kg |

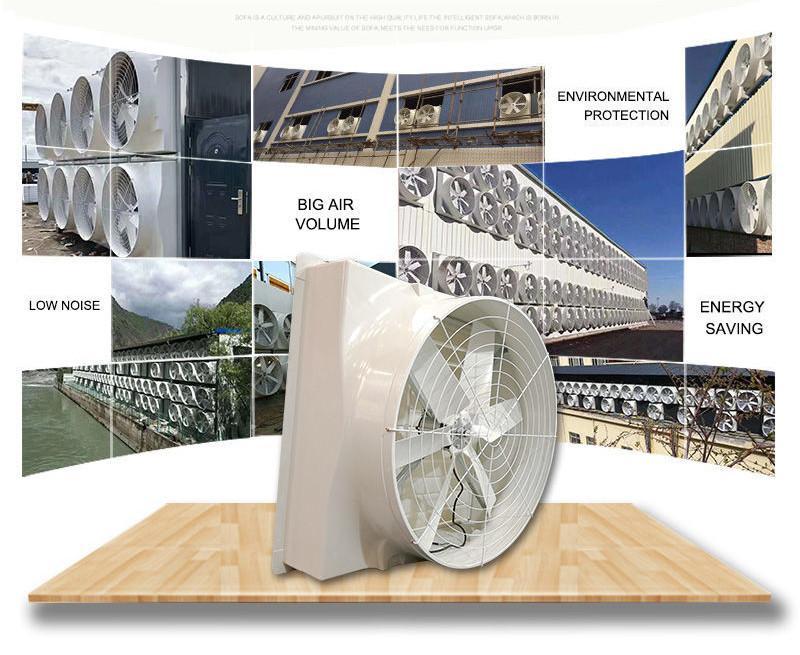

4. What is the advantage of FRP cone negative pressure fan?

1. Because the outer shell of the fan is composite material made of a polymer matrix reinforced with glass fibers, the corrosion resistant properties of fiberglass are wide ranging and suitable for use across the pH scale.

2. In addition to its corrosive properties, FRP provides a light weight and cost effective solution to its metal counterparts, it is not only minimum weight for easy installation and also provides safe working.

3. Marshine FRP negative pressure fan is used to quickly discharge the indoor hot air, exchange volume rate reach to 90%-97% and speed rate 60 ~ 120 times per hour so that the indoor temperature is equal to the external temperature, maximum indoor air ventilation and cooling.

4. Use of Marshine FRP negative pressure fan in the corrosive environments as livestock farm can maximum ventilation and cooling volume and minimum weight for easy installation and operate for a long time.

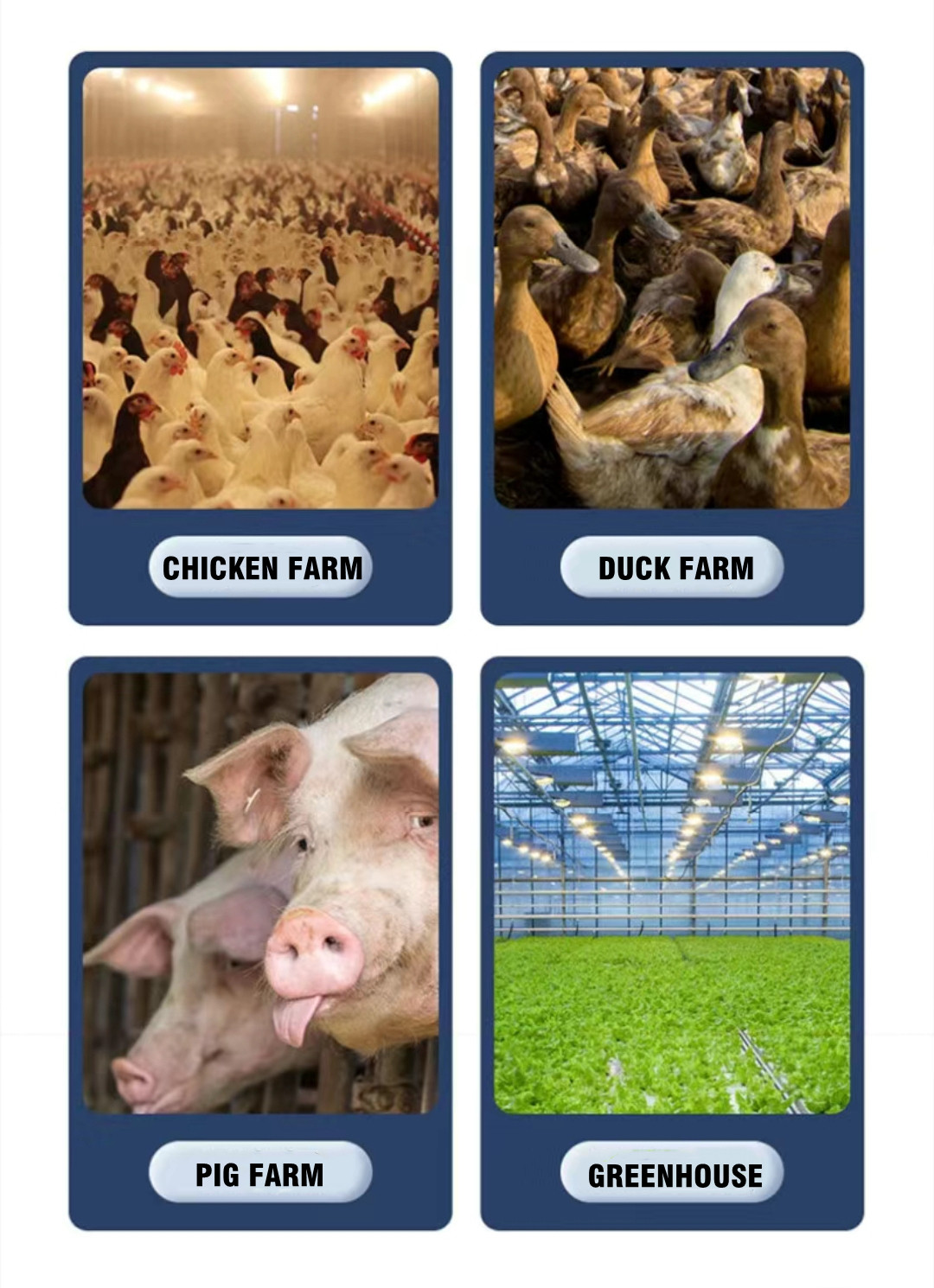

5. Where are frp cone negative pressure ventilation fans installed?

1. Industry: garment factory, plastic factory, electronic factory, electroplating factory, chemical factory, machinery factory, printing and dyeing factory, coal factory, etc;

2. Commerce: shopping malls, supermarkets, hotels, entertainment places, hotels, Internet cafes, etc;

3. Animal husbandry: ventilation in pig farms, chicken farms and rabbit farms;

4. Agriculture: garden flowers, greenhouse, aquaculture base, etc;

5. Places requiring cooling and humidity reduction. Such as cotton mill, wool mill, hemp mill, weaving mill, chemical fiber mill, warp knitting mill, texturing mill, knitting mill, silk mill, socks factory and other textile mills;

6. Applicable to warehousing, logistics and e-commerce.