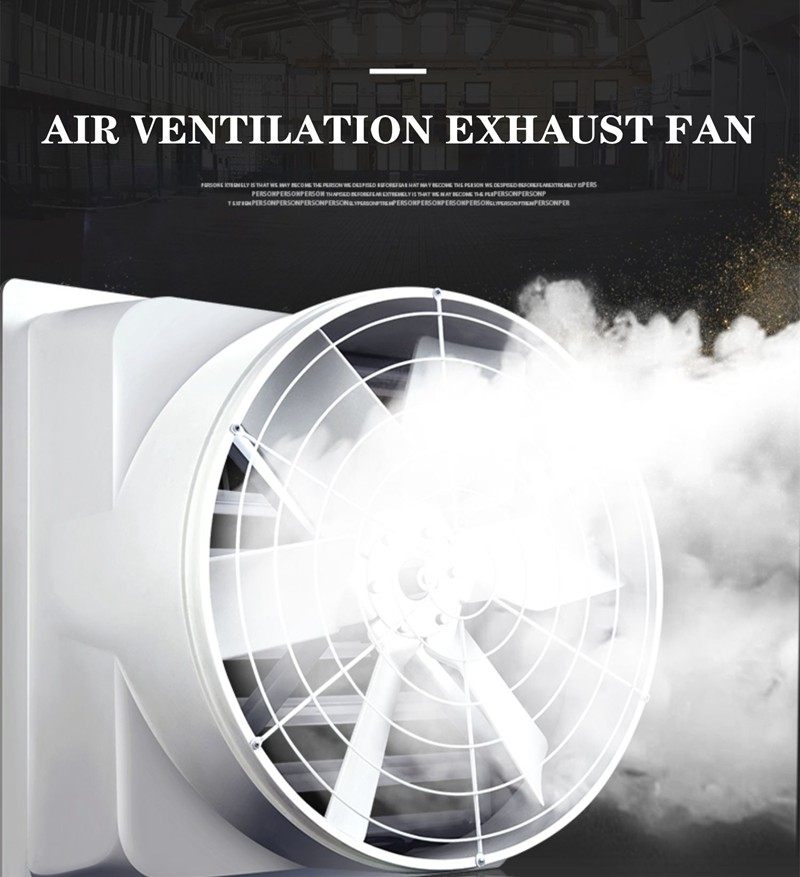

Heavy Duty Industrial & Commercial Exhaust Fans and Ventilation Fan System For Poultry Farm

560-Model 22” (inch) SMC FRP Ventilation Exhaust Fan

Table of Content

1. What is a fiberglass industrial & commercial exhaust fans?

2. What are the components of fiberglass industrial & commercial exhaust fans?

3. What are the types of commercial exhaust fans: Model MS-680, MS-850, MS-1060,

MS-1260,MS-1460

4. How to select industrial & commercial exhaust fans system for a poultry farmhouse?

5. How to install the fiberglass industrial & commercial exhaust fans and sizing it?

1. What is a fiberglass industrial & commercial exhaust fans?

Fiberglass industrial & commercial exhaust fans works in an independent space, such as the plant or the other end of the pipe to install an exhaust fan for ventilation equipment, is an independent space of the air to produce an in and out of the air flow, known as negative pressure, positive air supply known as positive pressure. Marshine Negative pressure can discharge hot gas, peculiar smell and dust out of the plant. Positive pressure ventilation means bringing in the fresh air from the outside into the poultry house through a fan to generate positive pressure and then discharge the turbid air through a vent on the other side.

In order to generate air convection in an independent space, in addition to the equipment, it is necessary to accurately calculate the total volume and area of the plant, the wind speed per second in the factory, and the ventilation frequency per hour of the whole plant.

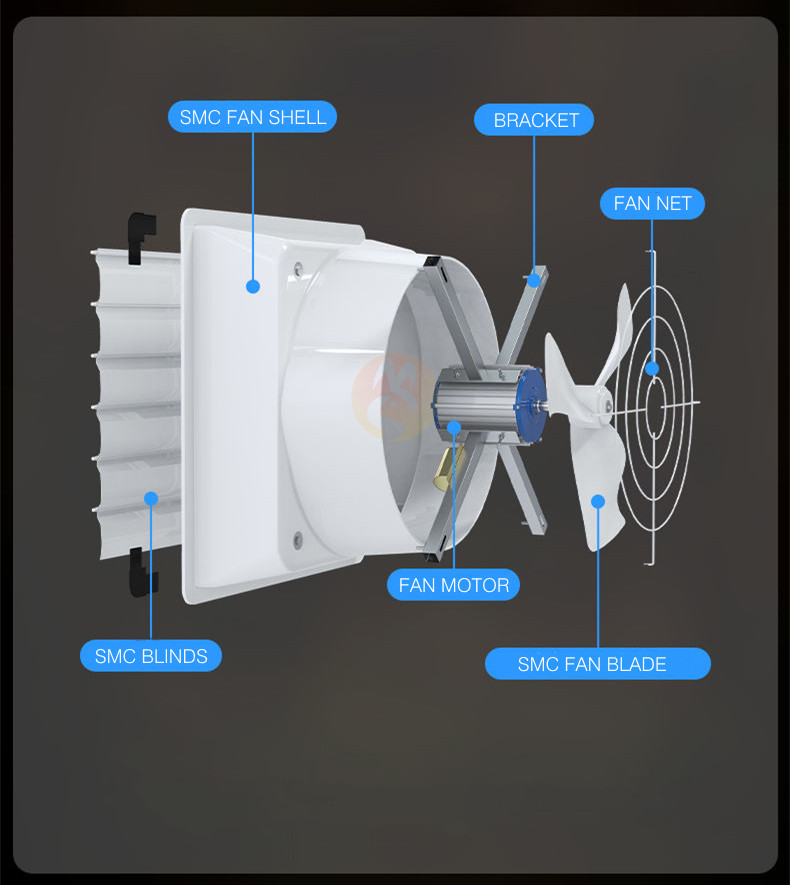

2. What are the components of fiberglass commercial exhaust fans?

For the material of farm use commercial ventilation exhaust fan, fiberglass among which the 304 stainless steel is the most durable material to choose, and it comes with high corrosion-resistance and rust-resistance. However, the cost of 304 stainless steel is too highest. That’s why fiberglass FRP SMC fan frame are used in most cases.

Fan Frame Thickness:

For Marshine 26 inch ventilation exhaust fan which is most often used in the greenhouse and poultry farm, 10mm thickness of the main fiberglass ventilation exhaust fan body will be very stability and durability. And the exhaust fan border thickness 18mm for comparably higher durability and strength installation. There are also manufacturers in the market who make the exhaust fans with 8mm thickness to meet the customers’ incredibly low budget for their projects, however, we don’t produce nor recommend this thickness to our customer for any kind of projects.

Shutters: As the fan frame, there are many material choices for the shutter material, fiberglass or PVC material will be a better choice, with higher anti-corrosion performance, longer service life, no deformation, no rust and more reliable operation..

Fan Blade: blades are the top most factor which affects the ventilation capacity of an poultry or greenhouse exhaust fan, the blade ventilation performance is up to the design and size of the blade, however, the durability and corrosion-resistance of the fan blade is up to the material of the blade, blade materials are fiberglass.

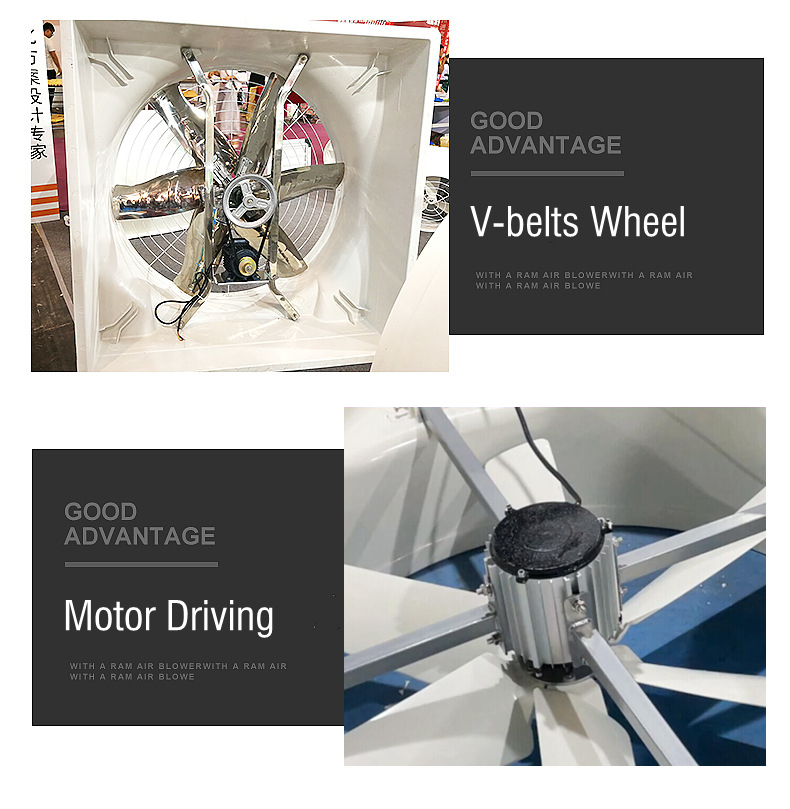

Belt: There are two types of belt you can select, but we will suggest you choose the B type belt because B type belt is 3 times longer service life than A type belt, and maintenance free.

Bearing: Marshine recommend you use one piece deep groove automotive bearing, with special design of waterproof, high strength, lower noise, maintenance-free, and long service.

Motor: The fan motor’ rotor is made of metal strip with copper coil or aluminum coils, the price of aluminum coil is much lower than copper coil, but the mechanical properties and electrical conductivity of copper are better than aluminum.

Motor Stents: there are materials of motor stents in the market, which include stainless iron, plastic and Marshine FRP pultrusion profile. The stainless iron material is heavy, it will result in loud noise and low wind speed. The plastic pulley is of low durability, the motor stens of Marshine is made of high strength fiberglass pultrusion rectangle tubes.

3. What are the types of industrial &commercial exhaust fans:

|

Item No. |

Dimensions(mm) |

Power(W) |

Air Flow |

Voltage/Frequency |

Noise |

Rotation Speed |

Net Weight |

|

560# |

560x560x440mm(22”x22”x17”) |

250W (3p) |

10000 m³/h 5900CFM |

380V/50Hz (customizable) |

≤45db |

950rpm |

35kg |

|

660# |

680x680x450mm(26"x26"x18”) |

250W (5p) |

12000 m³/h 7200CFM |

380V/50Hz (customizable) |

≤45db |

820rpm |

40kg |

|

850# |

850x850x480mm(33"x33"x19”) |

370W (8P) |

17000m³/h 10000CFM |

380V/50Hz (customizable) |

≤53db |

620rpm |

45kg |

|

1060# |

1060x1060x550mm(42"x42"x22”) |

550W (10P) |

28000m³/h 16600CFM |

380V/50Hz (customizable) |

≤55db |

560rpm |

50kg |

|

1260# |

1260x1260x560mm(50"x50"x22”) |

750W (10P) |

37000m³/h 22000CFM |

380V/50Hz (customizable) |

≤65db |

520rpm |

65kg |

|

1460# |

1460x1460x580mm(57"x57"x23”) |

1.1KW(10P) |

45000m³/h 26500CFM |

380V/50Hz (customizable) |

≤65db |

450rpm |

75kg |

4. How to Select Ventilation Fan System for A Poultry Farmhouse?

The ventilation fans for poultry farmhouses can be generally divided into two types, namely mechanical ventilation fan and natural ventilation fan. In design, it is quite necessary to pay attention to the thorough ventilation.

The required ventilation volume should be calculated based on the standard ventilation volume of each chicken and the number of the chicken, and then the number of fans to be installed is calculated according to their performance.

The windows should be placed symmetrically and evenly to ensure thorough ventilation in the poultry house. Meanwhile, open or close some windows according to the ventilation requirements to take advantage of both natural wind force and the ventilation effect of temperature difference.

Mechanical ventilation is the main method to regulate the internal environment conditions in case of a closed poultry house, high density of broilers, and breeding in large flocks. Ventilation is closely related to temperature control, humidity control, dust removal, and air composition adjustment.

5. How to install the fiberglass ventilation exhaust fan and sizing it?

1. The ventilation exhaust fan are fitted with a fiberglass reinforced plastic (FRP). The fan is then coated with a resin that is fire retardant. The components, such as the bearings, drives and fan shaft, are protected from corrosion in a couple of ways.

2. Some styles will use an air tight enclosure while others will draw fresh air from outside of the fan across the components. This ensures that corrosive fumes are not able to reach the moving components.

3. Access to inspect and maintain the internal components is available through an optional gasket access panel. To prevent fumes from escaping the drive opening a shaft seal is applied to the opening around the shaft.

4. Several considerations are made in order to reduce maintenance. The most important is bearing lubrication which is served by lubrication lines that run to the exterior fan housing.

5. Another is properly sizing the shaft and bearings for the performance and speed. This is performed to increase the fan’s lifecycle as well as and reduce maintenance. To isolate the motor from the airstream the motor is placed outside of the airstream on an adaptable epoxy coated steel base.