Fiberglass electric animal feed seed mixer stirring grain coating mixing machine

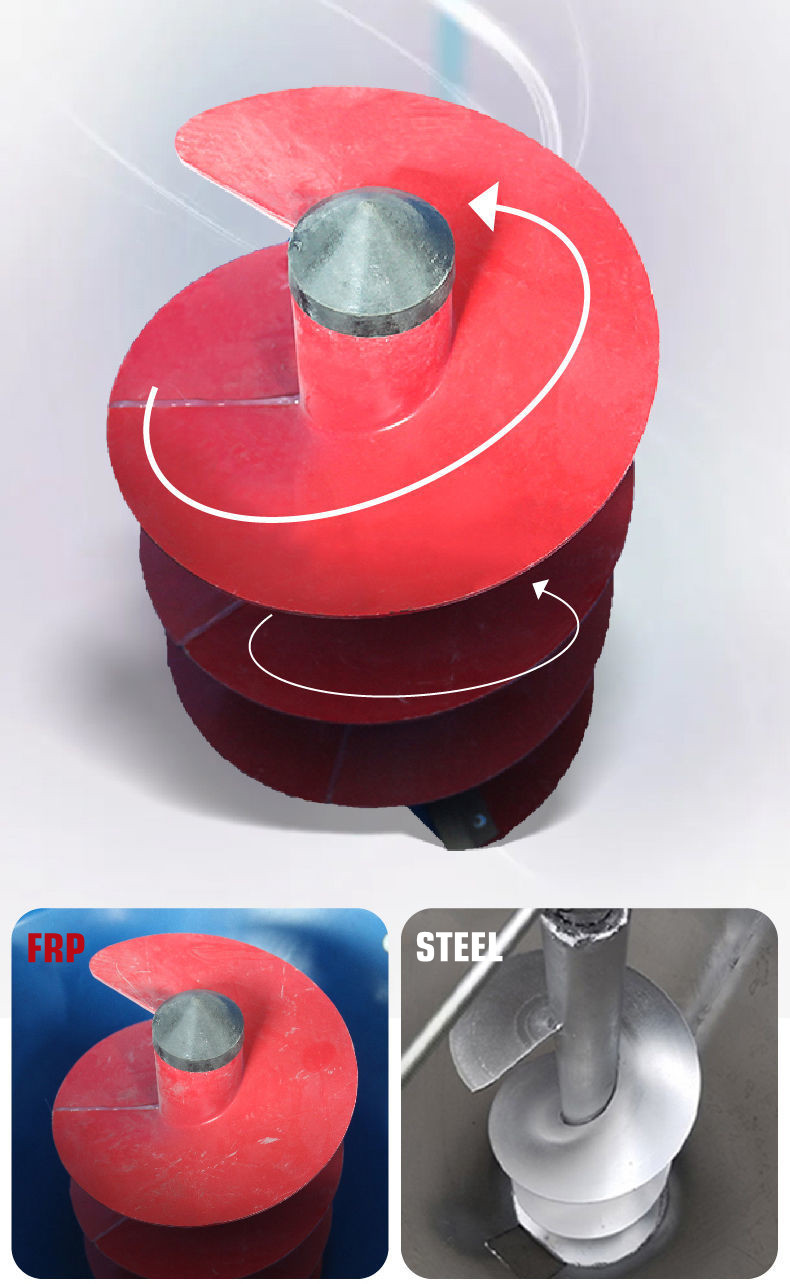

FRP feed electric mixer

1. Why fiberglass feed mixer is important in feed processing line?

Feed mixing is a key progress for good feed production. If feed is not mixed properly, ingredients and nutrients in feed will not properly distributed. It’s bad for animals that eating it. That’s why Marshine fiberglass feed mixer is always use as a important part of feed processing line.

1. Special material made of fiberglass reinforced plastic, which does not harm the integrity of feed pellets and corrosion resistance never rusted.

2. FRP electric seed blender can also stir seeds, for example: peanuts, beans, corn, wheat and other soft seeds.

3. The stirring speed is fast, the capacity of the mixer is 80-100 kg in a warehouse, and the mixer is stirred in 15-20 minutes. It can stir about 500-1000 kg per hour.

2. What is the specification and size for frp stirring grain machine?

|

Model |

Outer Size |

Power |

Maximum stirring capacity |

Stirring time per barrel |

Voltage |

|

ML-60 |

70*70*95 cm |

1.1 kw |

60-70kg |

2-5 minutes |

220V 50Hz or 380V 50Hz |

|

ML-100 |

77*77*105 cm |

1.5 kw |

100-120kg |

2-5 minutes |

|

|

ML-150 |

92*92*110 cm |

2.2 kw |

150-170kg |

2-5 minutes |

|

|

ML-200 |

96*96*125 cm |

3.0 kw |

200-240kg |

2-5 minutes |

3. What is the advantage of frp feed mixing machine?

1. The Marshine FRP electric mixer is equipped with a mobile rubber wheel, which is convenient for the mobile use of the machine. The user can push the electric mixer 45 ° to move, saving time and effort.

2. The fiberglass reinforced plastic electric mixer uses independent fiberglass reinforced plastic material impeller, which does not harm the integrity of the raw materials and is suitable for mixing soft materials.

3. Electric mixer add a stainless steel sealing cover to prevent items from being thrown during the mixing process.