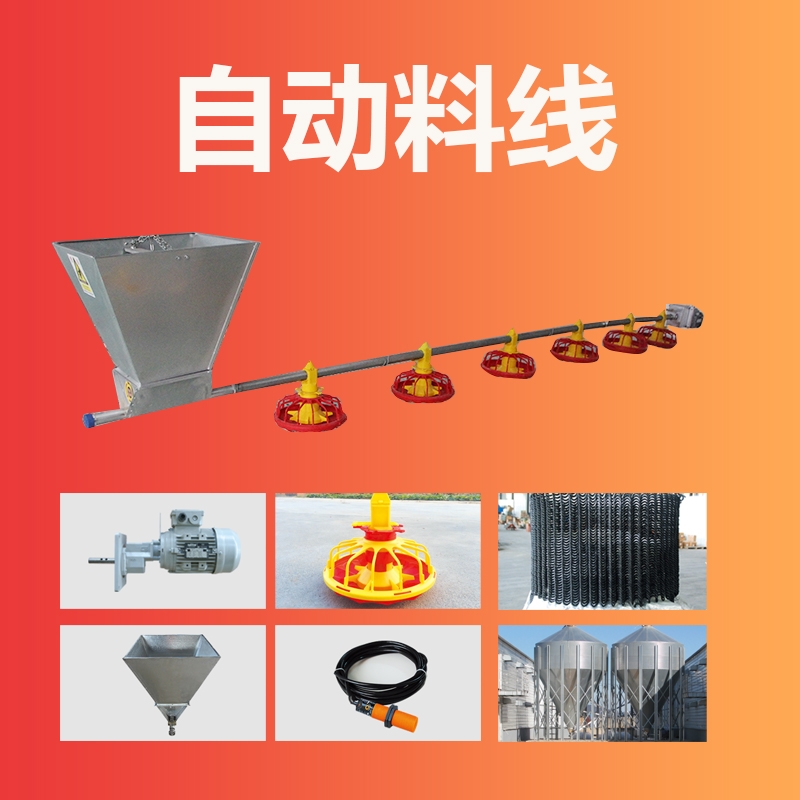

Commercial Automatic Chicken Broiler Pan Feeding System for Chicken Poultry Farm Feeding equipment

Automatic Chicken Feeding System

Table of Content

1. What is an automatic chicken pan feeding system and how does it work?

2. What components include in complete set of automatic chicken feeding system?

3. What is the size and type of the automatic chicken pan feeding system?

4. What are the advantages of automatic chicken feeding system?

1. What is an automatic chicken feeding system and how does it work?

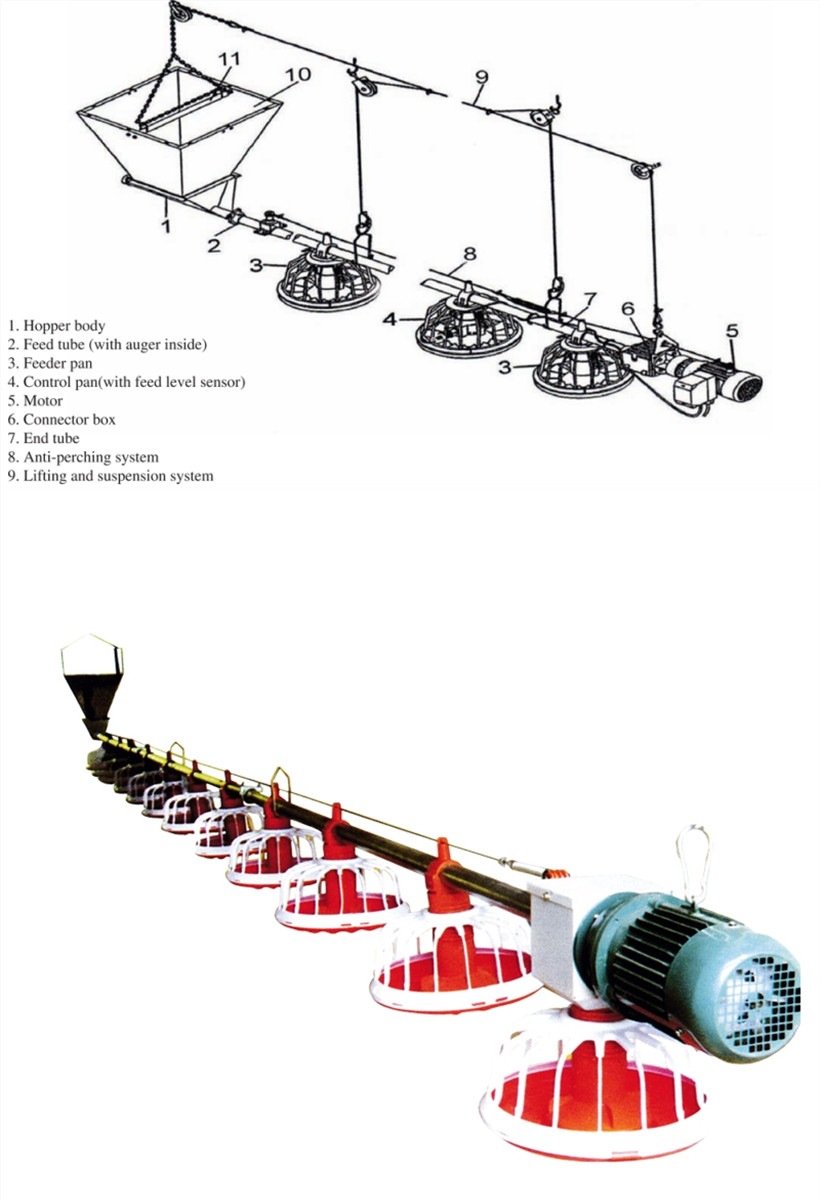

The Automatic Chicken Feeding System have two separated system, Main Feeding System and Pan Feeding System. Marshine Main feeding system delivers feed from the silo to the hopper in the poultry house. There is one feed sensor at the end of main feed line which control the motor on and off automatically to release automatic delivery. Marshine pan feeding system deliver feed automatically through motor under the control of feed sensor, which ensure birds feeding during whole growing period.

The main function of the system is conveying the feed from the hopper to each pan feeder for chickens. The automatic operation of the system is realized by the feeding level sensor to control the work or stop of the motor.

2. What components include in complete set of automatic chicken feeding system?

● Feed silo 8t/10t/14t

Feed silo adopts galvanized steel belt or fiber reinforced plastic, which is customized by the customer's demand; For galvanized steel (275g) or Marshine fiberglass (5mm) which is anti-erosive and ensures the long service life. Standard ladder and guard railing are safe and reliable.

● The hopper of automatic broiler feeding pan lines

The hopper is installed at the end of the feeding line or in the middle of the feeding line to feed the birds/broilers automatically and continuously. Marshine capacity 70kg hopper, 90kg hopper, and 120kg broiler pot feeding hopper are available now.

● Feeding level controller

To control the on-off of the drive motor, when there is feed in the hopper, the motor will be turned on. When the feed in the hopper is under the micro-switch, the motor will stop moving. The device prohibits the motor from feeding when there is no feed in the feed tubes.

●The pan feeder with limit leaf

Made by copolymerization PP or ABS (engineering plastics), low fat soluble, plus ourselves patent nostrum, to keep best tenacity and uv-resistant.4 feed pans/3m and 50-55 broilers/pan.

● The suspension system of the automatic chicken feeding system

3mm stainless steel wire, 3mm galvanized wire, and 6mm nylon rope could be chosen as the sling under customers' requests. However, the 6mm nylon rope is always introduced in practical engineering projects.

● Feeding pipe joint

The feed pipe is put up together by using pipe clamps.

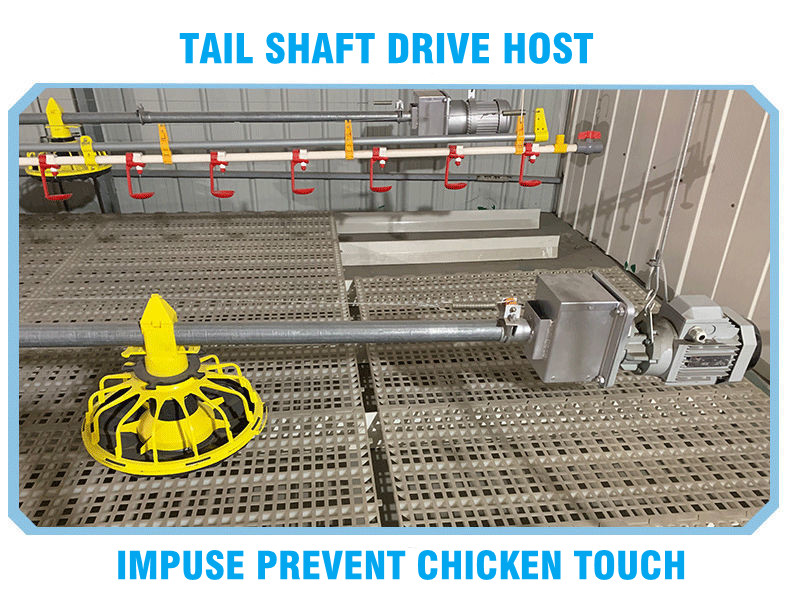

● The drive motor of the broiler pan feed line

Two kinds of split motors and integrated motors are optional for customers to choose for driving Marshine automatic broiler feeding system., the split motors are always recommended to reduce maintenance costs and prolong service life.

3. What is the size and type of the automatic chicken pan feeding system?

| 1. Feed Silo | 2mm thickness hot galvanized steel.Size: diameter 2.65m, 6 legs,Actual capacity 90%.Feed density 0.65ton/m3. |

| 2.Vice Hopper | Size: 70Kg, 90KgMaterial: hot-dip galvanized sheet, thickness:1mm |

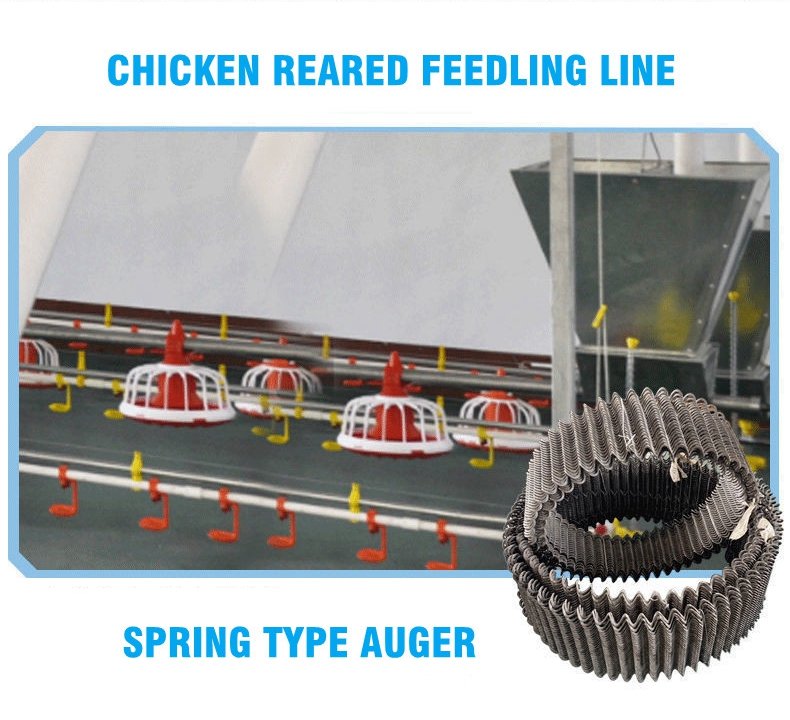

| 3.Feed Pipe | Feed pipe:Diameter of feed pipe:Φ45mmMaterial: hot-dip galvanized sheet pipe with the zinc coating amount—more than 275m2.Helical spring auger:imported from South Africa, feeding ability:450Kg/h |

| 4.Feed Pan | 4 feed pans/3m,Feed pan capacity:50-55 broilers/pan |

| 5.Control feed pan(with sensor) | imported from Germanytime delay range: 0-2hoursThe sensor is usually installed at the end of each Marshine feeding line which controls motor on and off to achieve feed delivery automatically. The motor will start working and convey feed when sensor doesn't touch feed, the motor will stop conveying feed when sensor touch feed. |

| 6.Driving motor | Taiwan brandPower: 0.75Kw/1.1Kw/1.5Kw,Voltage:380V/220V/others, three-phase/single-phaseFrequency:50Hz, AC current |

| 7.Connector box | Firm connection |

| 8.End tube | End tube position |

| 9.Anti-perching system | It prevents chickens from staying on the ground for too long. |

| 10.Lifting & Suspension | It's very convenient to adjust the feeding line height by winch. |

| 11.Hopper bin | Hopper bin position |

| 12.Cross beam | Cross beam position |

4. What are the advantages of automatic chicken feeding system?

1. Improve production efficiency, greatly increase production capacity, and have significant economic benefits

The use of Masrhine automatic feeding system to feed the chickens can ensure uniform feeding, so that the uniformity of chicken growth can be improved, and the laying hens can increase the egg production rate, prevents crop damage and provides comfort eating for chicken, efficiently to make sure the chicken gets food instantly.

2. Reduce manpower and greatly reduce production costs

The use of Marshine automated chicken raising equipment to raise chickens can automatically perform work instead of labor. This can save farmers the use of labor costs and reduce the cost of labor for farmers. The use of automated equipment is more convenient for mechanized operation, which can increase labor productivity to a large extent, that is, greatly reduce labor costs.

3. Easy to manage and reduce breeding risks

The use of Marshine automated equipment conducive to disease control and drug residue control, which creates conditions and lays the foundation for achieving the requirements of chicken hygiene and safety. The use of fully automatic poultry breeding equipment is the current direction to achieve intensive, standardized, efficient and high-quality breeding of layer and broiler chickens.